What is the Best Metal for Knives? A Comprehensive Guide

Scorpion Series Chef's Knife 9.5"

Are you on a quest to find the perfect knife but bewildered by the array of metals available? We're here to help.

1. Why It's Important To Know Knife Metals

Gladiator Series Chef's Knife & Cleaver Hybrid 8"

Like most niche interests, learning about knives is a multi-step process. First, you learn the stuff that's just under the surface – different types of knives beyond the tried-and-true chef's knife, for instance. Then you keep going down the iceberg and start to get into increasingly esoteric stuff. Before you know it, you're one of those bonafide knife steel nerds who knows all about the physical composition of their kitchen tools.

Understanding the type of steel used in your knife isn’t just about geeking out over chromium carbide formations or the nuances of powder metallurgy – although that’s certainly part of the fun. It's about matching the right metal to the right task, ensuring that your trusty blade isn't just another kitchen drawer casualty.

Knowing your metals

For instance, the hardness and toughness of your knife's steel can dramatically influence its performance. Harder steels maintain sharp edges longer, which sounds great until you realize they can be a nightmare to sharpen without the right sharpening stone. On the flip side, softer steels might need more frequent touch-ups but are generally more forgiving when it comes to ease of sharpening.

Then there's the question of the knife's purpose. A fixed blade made from VG10 steel, known for its superior ability to hold an edge, might be overkill if you're just opening letters, but it's ideal for a camping knife that sees all sorts of action from whittling wood to preparing meals.

Also, let’s not forget about S30V steel, a favorite among the pocket knife crowd for its excellent edge retention and overall durability. Developed through advanced powder metallurgy, this steel is designed to offer a perfect balance between edge retention, resistance to corrosion, and toughness -- making it a stellar choice for both everyday carry and specialized utility knives.

In the end, knowing your knife metals means you’ll be better equipped to choose a blade that doesn’t just perform well but also lasts longer and suits your specific cutting style. Whether you're a culinary enthusiast looking to slice through tomatoes like a samurai, or a weekend warrior whittling wood in the wilderness, the right knowledge can make your blade a cut above the rest.

2. The Key Properties Of Metal For Knives

Ronin Series Yanagiba & Sushi Knife 10.5"

When we explore knife metals, we start to see what each one brings to the table; from toughness and edge retention to corrosion resistance, and yes, even a hint of abrasive resistance for those tough-as-nails tasks. But just like any good team, it's all about finding the right balance -- too much of one power could overshadow the others, and suddenly your whole team is lopsided..

Let’s break down the properties of these metals a bit further:

Toughness Steels

These are the rugged defenders of the blade world. Metals with high toughness can take a hit and come back for more, which is crucial if you're using your knife for camping knives or as hunting knives where the unexpected is expected. But here's the twist: if a steel is too tough, it might not hold the finest edge. That’s where edge geometry and the right steel compositions play a crucial role.

Edge Retention

Steels that excel in edge retention keep on cutting, long after others have dulled. This feature is especially valuable in blade steels used for culinary pursuits where precision and consistency matter. However, such steels often require more effort to sharpen due to their hardness, which brings us to the importance of being properly cared for with tools like a good sharpening stone.

Corrosion Resistance

Gladiator Series Chef's Knife 8"

Ever had a knife rust on you? Not fun. That's why corrosion resistance is another key property. Steels with elements like chromium (think stainless steels) resist rust and maintain a clean look, making them ideal for kitchen environments or humid climates. Yet, these alloy steels sometimes sacrifice a bit of hardness for this resistance, nudging you towards a trade-off between performance and maintenance.

Read about the best (and safest!) way to clean your knives, here.

Abrasive Resistance

For those who like their knives to face the abrasive challenges of life -- be it cutting through fibrous materials or repeated usage -- abrasive resistance ensures that the knife not only maintains its edge but also its overall integrity. This trait is often bolstered by various alloying elements added into the steel types, enhancing the knife’s ability to resist wear and tear.

Incorporating these properties into steel knives isn’t just about mixing in as much of each trait as possible, but about crafting a balanced alloy that meets the specific needs of its user. Whether you’re in the market for a budget steel knife that offers a decent all-around performance or a high-end model designed for specific tasks, understanding these properties helps you pick a knife that’s not just effective but also a joy to use.

So, as you shop for your next knife, think about what kind of team' you want in your hand. Do you need the relentless durability of toughness steels, the enduring sharpness of advanced edge retention, the resilient shine of corrosion resistance, or the enduring character of abrasive resistance? Keeping these aspects in mind, you'll be able to choose wisely.

3. Knife Metal Composition

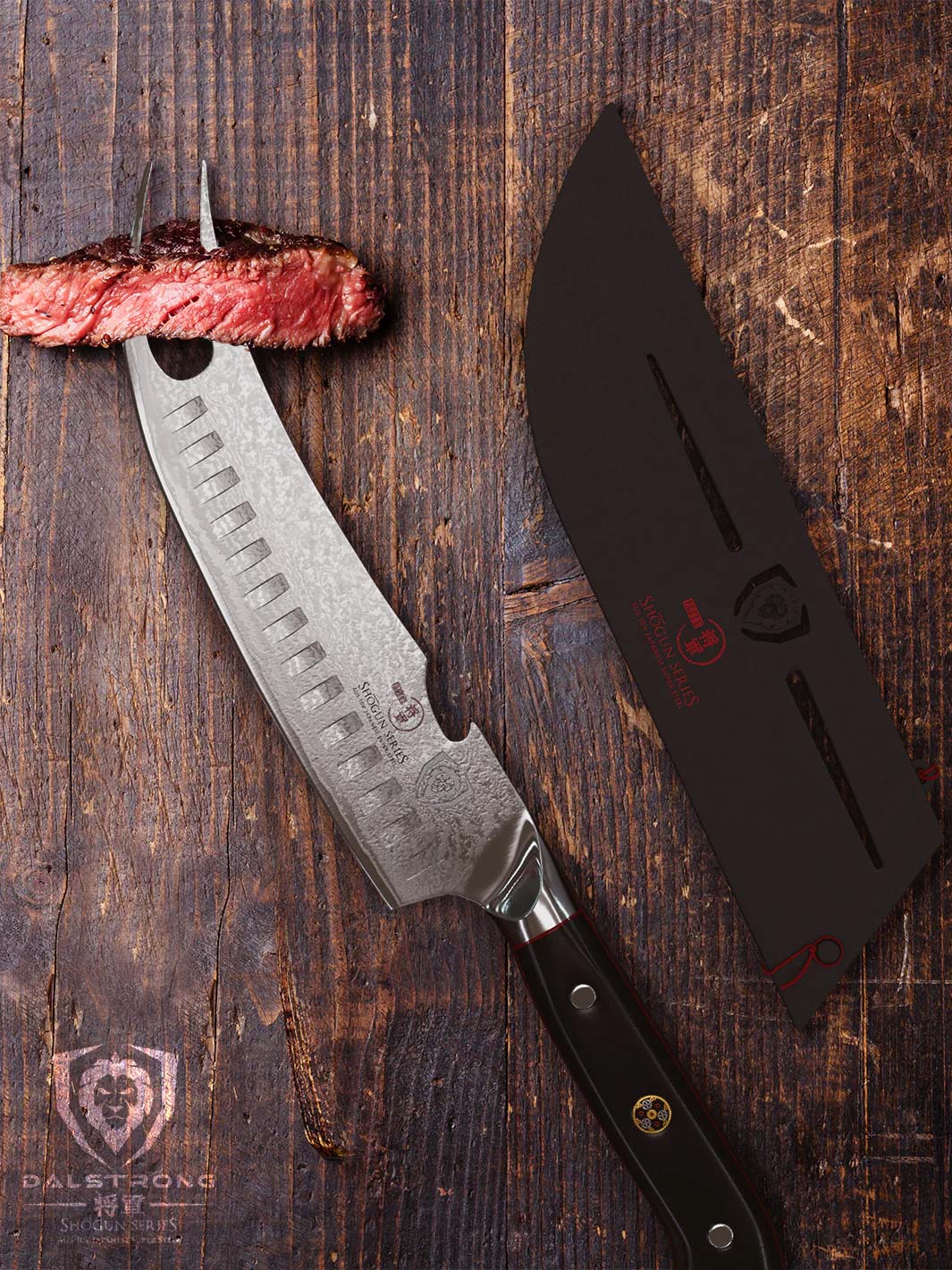

Shadow Black Series BBQ Pitmaster & Meat Knife 9"

There's a lot more going on with knife metals than you might think. Sure, we start with the basics: a good old mix of iron and carbon steels. But then, things get spicier when we add a dash of chromium -- not just a pinch, mind you, but varying amounts of chromium depending on how extremely corrosion resistant we want our knife to be.

Then there are the more exotic elements that join the mix. Vanadium carbides aren’t just there to sound cool; they’re like the secret spice that dramatically boosts the edge holding ability of the steel. Think of these carbides as the tiny, hard crystals that lock in sharpness, making your knife not just tough but a real contender in the edge retention game.

Speed steel

Speaking of hard, let's talk speed steel -- a variety of steel that’s designed for, you guessed it, high-speed performance. This isn’t your grandma’s butter knife. Speed steel is crafted to endure the rapid, repetitive motions seen in industrial settings, which translates beautifully to the repetitive tasks of chopping and slicing in your kitchen.

Carbon content

As far as the carbon content, amounts of carbon can vary widely. Low carbon steels are more ductile and easier to shape, which makes them incredibly easy to sharpen. On the other end, high-carbon steels, which pack more carbon, bring out a harder, more edge holding prowess. This variety ensures that whether you’re a home chef or a wilderness explorer, there’s a perfect mix out there for your blade.

Series steels

Now, not to forget the series steels, which are categorized based on their specific compositions -- like the 400 series that are popular for their good corrosion resistance and ease of maintenance. Each series has been engineered with specific traits in mind, blending elements to achieve the best possible performance for its intended use.

This tailored approach to metal composition means that no matter your cutting task, there’s likely a knife that’s been mixed, melted, and molded just right for the job. It’s this careful concoction of elements that turns a simple blade into a precise cutting tool, ready to tackle the toughest tomatoes or the most rugged backcountry tasks.

So to summarize, here's a list of the elements you might find in knife steel, and what they each bring to the table:

- Carbon: Boosts hardness and enhances edge retention.

- Chromium: Enhances both hardness and resistance to corrosion.

- Molybdenum: Bolsters toughness.

- Nickel: Augments toughness.

- Vanadium: Improves wear resistance.

- Cobalt: Amplifies hardness.

- Manganese: Elevates strength and wear resistance.

- Silicon: Strengthens the metal.

- Niobium: Boosts corrosion resistance and enhances wear resistance.

- Tungsten: Strengthens toughness and wear resistance.

- Sulfur: Improves machinability.

- Phosphorus: Enhances corrosion resistance and increases hardness.

- Nitrogen: Elevates corrosion resistance and hardness.

- Copper: Promotes deoxidation.

- Aluminum: Aids in deoxidation.

- Boron: Increases hardenability.

- Lead: Enhances machinability.

- Selenium: Improves machinability.

- Tantalum: Increases hardness and boosts wear resistance.

- Zirconium: Enhances toughness.

4. What Are The Common Metal Types For Knives

Valhalla Series Chef's Knife 8"

Welcome to the metallic mixology of knife making, where the choice of metal determines the chef’s delight or the adventurer’s reliability. Each type of metal brings its own unique set of characteristics to the table, or should we say, to the cutting board! Let’s slice through the details of these popular metals and discover their secret sauces:

Metal Types for Kitchen Knives

Stainless Steel

Whether it's a chef's knife or a utility knife, this is one of the most popular types of knife steels. This metal is highly corrosion resistant and shines with ease of maintenance, making it a favorite among those who prefer a no-fuss cleaning routine. However, it can be a bit difficult to sharpen due to its hardness, which is a small price to pay for its resilience against rust and tarnish.

For some great stainless steel knives, check out the knives in Dalstrong's Crusader series. Here are two of them:

1. Crusader Series | Santoku Knife 7"

This all-stainless steel 7-inch knife is a triple threat for slicing, dicing, and mincing. It's got divots and a nifty groove along the blade to keep things from sticking and to make your chopping smoother.

PROS:

- Crafted from high carbon ThyssenKrupp German stainless steel, this knife is seriously sharp and built to last.

- The edge is hand sharpened to a keen 16-18 degrees per side, perfect for those paper-thin tomato slices.

- The handle feels just right in your hand, making it easy to maneuver and comfy even during those marathon meal preps.

- Comes with a cool Acacia wood magnetic sheath, which isn’t just practical but also looks great on any kitchen counter.

CONS:

- The modern stainless steel handle might not be everyone’s cup of tea if you’re into classic wooden handles.

- Because of the hollow handle, it's lighter than you might expect!

2. Crusader Series | Serrated Utility Knife 5.5"

Got a sandwich to build? Grab the Crusader Series 5.5” Serrated Utility Knife and make your kitchen prep a breeze. This knife tears through bread, tomatoes, and even the slickest cucumbers without a hitch, and its narrow blade zips through cheeses like cheddar or swiss without sticking.

PROS:

- Precision forged from high carbon ThyssenKrupp German stainless steel, this knife is ultra-sharp and ridiculously durable.

- Designed with a serrated edge sharpened to 16-18 degrees per side, it's a pro at making clean cuts through crusty bread and soft fruits alike.

- The stainless steel handle is sleek, easy to clean, and feels solid yet comfortable in your hand, perfect for those longer prep sessions.

- Like its Santoku cousin, it comes with a nifty Acacia wood magnetic sheath that not only protects the blade but also adds a touch of class to your kitchen.

CONS:

- If you're not a fan of serrated edges, this might not be the knife for you, as they require a bit different technique and maintenance.

- The narrow blade is great for sandwiches and cheeses but might not be as versatile for other kitchen tasks as the broader Santoku.

Carbon Steel

This is the old-school hero with a modern twist. Known for its exceptional edge retention, carbon steel is perfect for those who love a sharp, durable edge. However, it demands a bit of love in return to ward off rust, making it a great choice for the culinary artist who respects the blade's craft.

Here are a couple of great high carbon steel knives!

1. Quantum 1 Series | Butcher & Breaking Knife 10"

This 10-inch powerhouse is great for tackling big game meats and more with futuristic precision. Engineered with cutting-edge blade technology, this knife makes short work of even the toughest carving jobs.

PROS:

- Made from high carbon American BD1N-VX steel, hardened to an impressive 63+ HRC with a vacuum heat seal, this blade is not just sharp, it’s lastingly sharp.

- Its edge is honed to a razor-sharp 8-12° per side, perfectly balancing supreme sharpness with outstanding durability.

- Features a “Nova Prime” blade pattern that not only looks cool but reduces drag and boosts cutting efficiency.

- The ergonomic Fiber-resin military grade G10 & Carbon Fibre Hybrid handle is tough as nails, resistant to heat, cold, and moisture, making it nearly indestructible no matter the environment.

CONS:

- The high-tech materials and advanced design might be overkill if you’re just looking for a basic kitchen knife for everyday tasks.

- Its impressive size and cutting prowess require a bit of practice to handle safely and effectively, especially if you're new to using such a specialized tool.

2. Quantum 1 Series | Cleaver Knife 7"

Talk about a cleaver. This is a powerhouse built with some of the most advanced knife technology out there, ready to take on boneless meats, poultry, veggies, and fruits without breaking a sweat.

PROS:

- Crafted from American-made BD1N-VX hyper-steel, this cleaver achieves a whopping 63+ Rockwell Hardness, ensuring your blade stays razor-sharp, use after use.

- The blade features a nitrogen treatment for increased flexibility and durability, letting you chop with precision and ease.

- With its ergonomic Dragon Skin G10-carbon fibre handle, this knife promises top-notch grip and maneuverability in any kitchen scenario, hot or cold.

- The "Nova Prime" blade pattern looks awesome, plus it reduces drag and stuck on the food!

CONS:

- If you're looking for something a little more versatile, try a chef's knife instead.

- It's pretty hefty! Might take you by surprise if you're not expecting it.

Damascus Steel

Not just a feast for the eyes with its wavy, mesmerizing patterns! Damascus steel offers a blend of toughness and fine edges, making it ideal for precision cuts. Though it might pinch your wallet, the investment translates into a blade that's as functional as it is beautiful.

1. Scorpion Series | Chef's Knife 9.5"

Got a lot of chopping, slicing, or dicing on your plate? The Scorpion Series 9.5” Chef Knife might just be your new kitchen MVP. It’s got a longer blade with a sweet curve and a sharp tip that’s perfect for all kinds of kitchen tasks—from rock-chops to skinning meats. Plus, it's toughened up with cobalt for extra durability against kitchen wear and tear.

PROS:

- The blade features an awesome Damascus pattern, thanks to 69 layers of steel and a nitrogen cooling finish, making it as stylish as it is sharp.

- The added cobalt in the blade not only enhances wear resistance but also maintains its hot hardness, allowing it to withstand the intense, prolonged use often found in busy kitchen environments.

- The handle is designed to handle extreme temperatures and resist scratches, keeping it looking good after use.

- With an edge sharpened to 8-12° per side and a handle built for comfort, this knife makes prep work feel less like a chore and more like a breeze.

CONS:

- Its high-end materials and design features might be overkill if you’re just looking for a simple chef’s knife for everyday cooking.

- The distinctive style and premium build mean it comes at a higher price point, which might not fit everyone’s budget, especially if you're not using it professionally.

2. Shogun Series X | Nakiri Vegetable Knife 6"

This thing is a powerhouse for chopping through root veggies and squash, thanks to its super sharp edge and sturdy feel. Plus, it's got this cool hammered finish that's not just for show—it actually helps keep food from sticking as you chop.

PROS:

- It’s made from a super tough 66-layered Damascus steel with a core of Japanese AUS-10V steel, so it stays sharp and holds up well over time.

- The cryo-treated steel makes the blade both strong and flexible, which is great when you’re dealing with tough veggies or want to get really precise with your cuts.

- The handle and blade design give you lots of clearance for your knuckles, so it’s comfy to use, even during a big prep session.

- It comes with a neat sheath that not only looks good but keeps your blade in top shape when you’re not using it.

CONS:

- This knife is on the pricier side of our list here, which might be a bit much if you’re not super serious about your kitchen tools.

- The bold red handle and detailed design might not be for everyone, especially if you like your knives a bit more on the subtle side.

AUS Series

These steels strike a happy medium in the knife world. AUS8 steel, for instance, offers commendable resistance and edge retention without being overly pricey or demanding. It’s the reliable friend in your kitchen that you can turn to for almost any task.

Tool Steels

Steels like CPM M4 are the heavy lifters of the knife steel family, offering outstanding wear resistance and edge quality. Ideal for those who don’t mind giving their knives a bit of TLC, these steels reward you with performance that can handle the toughest tasks.

Types of Metal Used in Other Types of Knives (Non-Kitchen)

D2 Steel

A favorite for tactical knives and survival knives, D2 steel brings to the table high hardness and significant resistance to corrosion. It’s the type of steel you want on your side when heading into tough environments, making it a top pick for outdoor enthusiasts.

M390 Steel

Often described as a high-end steel, M390 is prevalent in everyday carry and pocket knives. Renowned for its superior edge retention and corrosion resistance, this steel is for those who demand the best from their blades, ensuring peak performance day in and day out.

CPM S110V

The crème de la crème for those who prize sharp edges and stellar super steel performance. This steel is a prime choice for engraved knives and folding knives, providing a long-lasting edge that’s sure to impress both in function and form.

Each of these metals has been crafted to meet specific needs, from the casual cook to the serious survivalist. Choosing the right metal isn't just about picking a knife; it's about selecting the right partner for your culinary creations and outdoor adventures. Whether you're finely chopping vegetables or fending off the wilderness, there’s a perfect blade waiting to be wielded by you.

5. What To Consider When Choosing The Best Metal For Knives

Vanquish Series Chef's Knife 8"

Now that you're more well-versed when it comes to metals for knives, it's time to start searching for the right knife for your kitchen. It's important to find the right knife for you, whether you’re slicing tomatoes finely in the kitchen or using the knife as a trusty sidekick on a camping adventure.

Here's how to keep your decision sharp and well-informed

Purpose of the Knife

What's your knife's main gig? If your days are spent crafting gourmet meals, a knife that offers precision, such as one made from high-carbon steel, might be your star performer. On the other hand, if you're out battling the elements, you’ll want a robust buddy like a stainless steel blade that laughs in the face of rust and corrosion.

Level of Corrosion Resistance

If you're a beach camper or a fish fillet master, the level of corrosion resistance is a big-ticket item. Salty air and moisture are real threats to a blade's longevity. Materials like stainless steel or specially treated steels can offer peace of mind by holding their own against the elements. No one likes a rusty blade, especially when you’re prepping dinner after a day of surfing waves or hiking trails.

Maintenance and Sharpening

How often do you want to be honing your blade? Some steels hold an edge longer but can be a bear to sharpen once they do dull. If you're not keen on frequent sharpening sessions, consider a blade with good edge retention. But remember, harder steels require more effort and the right tools (like a diamond sharpening stone) to get back to that razor-sharp edge.

Budget Considerations

Just as you wouldn’t use a sledgehammer to crack a nut, you don’t need to blow your budget on a super steel if your needs are more basic. Budget steel options can provide excellent service without the premium price. But if you’re looking for that perfect slice with every chop, investing in a higher-end steel could be worth every penny.

Choosing the best metal for your knife is about striking a balance between these factors. It’s not just about having a knife that cuts; you want one that feels right in your hand and suits your lifestyle, whether you're a kitchen connoisseur or an outdoor adventurer. After all, a great knife is an extension of your hand and an indispensable tool in your culinary or camping arsenal.

6. Frequently Asked Questions

Which metal is best for knife blades?

The best metal for knife blades often depends on your specific needs, but for overall versatility and maintenance ease, stainless steel blades are frequently a safe choice. They offer a great balance of durability and corrosion resistance, making them ideal for both kitchen and outdoor use.

What is the best metal to make sharp knives?

For achieving exceptionally sharp edges, CPM S30V and CPM S110V steels are highly regarded. These steels are designed to maintain sharpness over prolonged use, making them perfect for applications where precision cutting is crucial, such as in fine culinary tasks or detailed crafting.

What knife steel gets the sharpest?

Damascus steel knives are known for their ability to become extremely sharp and maintain their edge, thanks to specialized heat treatments that enhance their properties. The unique layering process not only creates striking visual patterns but also contributes to the sharpness and durability of the blades.

What are 3 metals used for knives?

Three commonly used metals for knives include stainless steel, carbon steel, and Damascus steel. Stainless steel is valued for its corrosion resistance and ease of maintenance, carbon steel is favored for its superior edge retention, and Damascus steel is renowned for both its functionality and distinctive aesthetic appeal. Each type offers unique benefits, catering to different cutting tasks and preferences.