End Grain Cutting Board: Your Knife’s Best Friend

Lionswood- Teak Cutting Board | Dalstrong

Lionswood- Teak Cutting Board | Dalstrong

I often hear professional chefs and seasoned cooks talk about how knives are only as good as the cutting board they are being used on. I never truly understood what that meant until I decided to do away with my old piece of wood and invested in a gorgeous Dalstrong cutting board.

A good reason to choose a cutting board wisely is the risk of food-borne illnesses from a cracked or scratched surface. A cutting board made of good quality wood can last for years but if you invest poorly, you might end up regretting your pick every time you use it. So, if you need a little help with picking a cutting board that would fit all your kitchen needs, you’ve reached the right place.

While you might see a plastic cutting board or a bamboo cutting board very often at your local store, wood is the most popular material when it comes to cutting boards! Wood is more sanitary, durable, and cut-resistant than plastic. Wooden chopping boards also require less maintenance than marble or granite cutting boards. However, wooden boards vary in quality and durability based on how the wood used to make the board is cut. This is called the wood grain of the board.

There are 3 types of cutting board wood grains- end grain, edge grain, and face grain. End grain cutting boards prove to be the most durable out of these. Let’s take a look at what makes this wood the most suitable to bear the kitchen heat and survive for many years.

1. What Is An End Grain Cutting Board?

Lionswood Colossal- Teak Cutting Board | Dalstrong

Lionswood Colossal- Teak Cutting Board | Dalstrong

End grain cutting boards have a very unique structure as compared to regular cutting boards. What sets them apart is that the wood grains are perpendicular to the cutting surface and not parallel. This means that the board is constructed so that the fibers of the wood face upwards and make up the cutting surface.

Boards like these need more individual pieces of wood and are generally more difficult to make. This is one of the main reasons why these boards tend to be more expensive than their counterparts. The functionality of this is pretty simple- the orientation of the wood fibers handles the sharp edge of a blade better than the long edge of a wooden plank.

Even if a blade is caught in between the natural separation of the fibers, they close back up over time, which is why boards like this carry a reputation for being self-healing. Other than this, it is also a more universal and cost-effective wood end grain chopping board option for those who spend a lot of time in the kitchen. If properly maintained, they are also more sanitary and prevent the board from filling up with bacteria.

2. End Grain VS Edge Grain Cutting Board

Dalstrong Teak Wood Corner Board

Dalstrong Teak Wood Corner Board

|

Characteristic |

End Grain Cutting Board |

Edge Grain Cutting Board |

|

Type of Wood |

This is made by cutting up a slab of lumber into smaller blocks and gluing the blocks back together in a way that the end grain of the blocks forms the boards working surface. |

This is made by fusing small slabs of wood in a way that the side edges of the pieces from the surface of the chopping boards. The faces of wooden slabs are glued together so that the edges become the cutting surface. |

|

Durability |

They are the most durable as they can hide knife marks. End grain boards also rarely split or break away since they’re very thick. |

They are more durable than face grain cutting boards as they are harder and absorb less moisture. However, the wood is not as sturdy and hard as an end-grain cutting board. |

|

Weight |

The wood used to make these boards is hard, which makes them heavy. This is why end grain construction is also used to make butcher blocks for cutting, deboning, and fileting meat. |

These boards are less thick and lighter than end grains due to their simple construction and design. |

|

Hygienic |

These boards experience shallow, superficial cuts and get back into shape when cut. This means that small bits of food can’t get stuck deeply on the board’s surface. |

These boards absorb more moisture and can get permanent cracks where food can get stuck. If not maintained, these boards can become a breeding space for bacteria. |

|

Response to sharp blades |

It’s more spongy and rougher in structure than edge grain. This increases the knife’s grip when cutting food and prevents the knives from blunting. |

These boards show knife cuts and scratch marks. |

|

Affordability |

Due to the high cost of labor required to construct each board, they turn out to be expensive. Since the pieces are assembled, construction is mostly done by hand. |

If you are looking for a budget-friendly board, this one would be a great option. They are less expensive than end grain boards and sit in the sweet spot between price and performance. |

|

Appearance |

These boards are made by assembling several individual pieces of wood which gives the surface a beautiful and unique pattern. This construction ensures that every board is one of a kind. |

Almost all edge grain boards look similar. |

3. Best Woods For End Grain Cutting Boards

Corner Cutting Board - Teak Wood

Corner Cutting Board - Teak Wood

Teak

Boasting a hardness rating that’s better than any other kind of wood, teak holds up better to scratches and impacts than walnut wood. As a tropical close-grained hardwood, teak costs the most. Teak wood cutting boards are naturally resistant to water, bacteria, and staining.

Visually, teak is a beautiful wood with a medium brown color tinge and gold and orange hues. The grain of this wood is sharp, fitted, and uniform in texture, making it very appealing. Teak also shrinks less than any other wood, so maintaining it is simple.

Maple

Both soft and hard maple make for excellent chopping surfaces. But hard maple is the industry standard among cutting board makers. This wood is also scratch and impact resistant. This food-safe, closed-grained hardwood has smaller pores than most other woods, enhancing its bacteria, moisture, and stain-resistant qualities. But when this wood does stain, the off-white to amber-yellow surface becomes hard to hide.

Maple cutting boards and butcher blocks cost more than beech wood. This material also shrinks more than teak and walnut as humidity decreases. You have to keep conditioning the board to make sure it lasts for a long time.

Beech

This food-safe, closed-grained hardwood does not damage knives and offers amazing scratch and impact resistance. Its small pores make it nearly as effective as maple at warding off bacteria, moisture, and stains.

These cutting surfaces are generally the cheapest. They also shrink more than any other wood mentioned here which is why it needs regular conditioning.

Walnut

This is the softest of the closed-grained hardwoods mentioned. Walnut wood is unlikely to dull a knife’s blade but it scratches and dents more easily than the other woods.

The medium to large posters of this food-safe wood offer less resistance to bacteria and moisture than maple or beech. This rich chocolate-colored hue of the wood masks stains well and lends countertops a high-end look.

4. Tips To Pick The Perfect End Grain Cutting Board

Lionswood | Teak Cutting Board | Dalstrong ©

Lionswood | Teak Cutting Board | Dalstrong ©

Here are some things to keep in mind when investing in a wooden cutting board:

Hardness Rating

The higher the hardness rating of wood, the harder and more resistant it is to scratches, dents, or dings from knives. Remember to opt for hardwoods like teak over softwoods like pine as they have a higher hardness rating and are less damage-prone.

Porosity

Pick closed-grain woods to keep liquid or bacteria from entering the cutting surface and causing mold growth, wood warping, or stains. Remember, the smaller the pores, the better. Open-grained woods like oak or ash are poor choices because they soak up moisture and quickly become a breeding ground for bacteria.

Toxicity

Go for woods that produce audible fruits, nuts, and leaves, and they are considered to be food-safe. Exotic woods like Purpleheart might look attractive but should be avoided as they often contain toxins that could leach out of the wood and into food places on the board.

Conditioning

Some boards require more conditioning than others. You must always apply food-grade mineral oil to condition cutting boards and butcher blocks. This helps suppress wood’s natural tendency to shrink and warp or split as humidity decreases. You should be conditioning your wooden cutting board quarterly, however, some woods shrink more, so they would need to be oiled more frequently.

Cost

Store-bought cutting boards can vary in price depending on the wood used to make them. Generally, cutting boards turn out to be less expensive than butcher blocks. You must have a budget in mind when looking to invest in a cutting board to avoid confusion.

5. How To Maintain An End Grain Cutting Board

Teak Wooden Cutting Board | Dalstrong ©

Teak Wooden Cutting Board | Dalstrong ©

Let’s take a look at some ways in which you can ensure that your end grain cutting board lasts a long time:

- Wash the cutting board with soap and warm water and scrub well. Scrubbing will help make sure that all the bacteria are washed off the board.

- Dry the board immediately with a towel after washing it and let it air dry standing up or on a raised rach with airflow.

- Do not put the board in the dishwasher as the heat will cause the board to warp.

- Do not let the board sit in water for too long as it could absorb water and warp.

- Avoid using bleach on your end grain chopping board as it will stain the board and dry the wood.

- If the board smells or has stains, you can use lemon juice or white vinegar directly on the area.

- Oil the cutting board only once it's fully dry.

- Be generous with the amount of oil you use as you want the surface to be dripping wet on all sides. Let the oil soak into the cutting board for as long as possible.

- You can also apply board cream once the board is dry after washing or oiling. A small amount of cream can be circularly buffed on the surface, forming a thin coat.

- I suggest you oil and apply the cream to your cutting board at the same time.

6. Top End Grain Cutting Board Picks For You

1. Teak Cutting Board- Medium Size | Dalstrong

This perfectly sized cutting board will assist you with your everyday chopping and cutting tasks. Crafted with 100% sustainably sourced Tropical Teak wood, this board is designed to look better as it ages.

Pros:

- This board is just the right size to fit into even a compact kitchen without taking up much space.

- The lasered measurement lines on the bottom of the board help make precise cuts of meat and allow for easy sectioning.

- The board with a juice groove helps messy prep stay on the board.

Cons:

- If you are someone who handles large quantities of meal prep, you might want to go for a bigger cutting board.

- The board does not come with handles, so lifting it from one place to the other can be challenging.

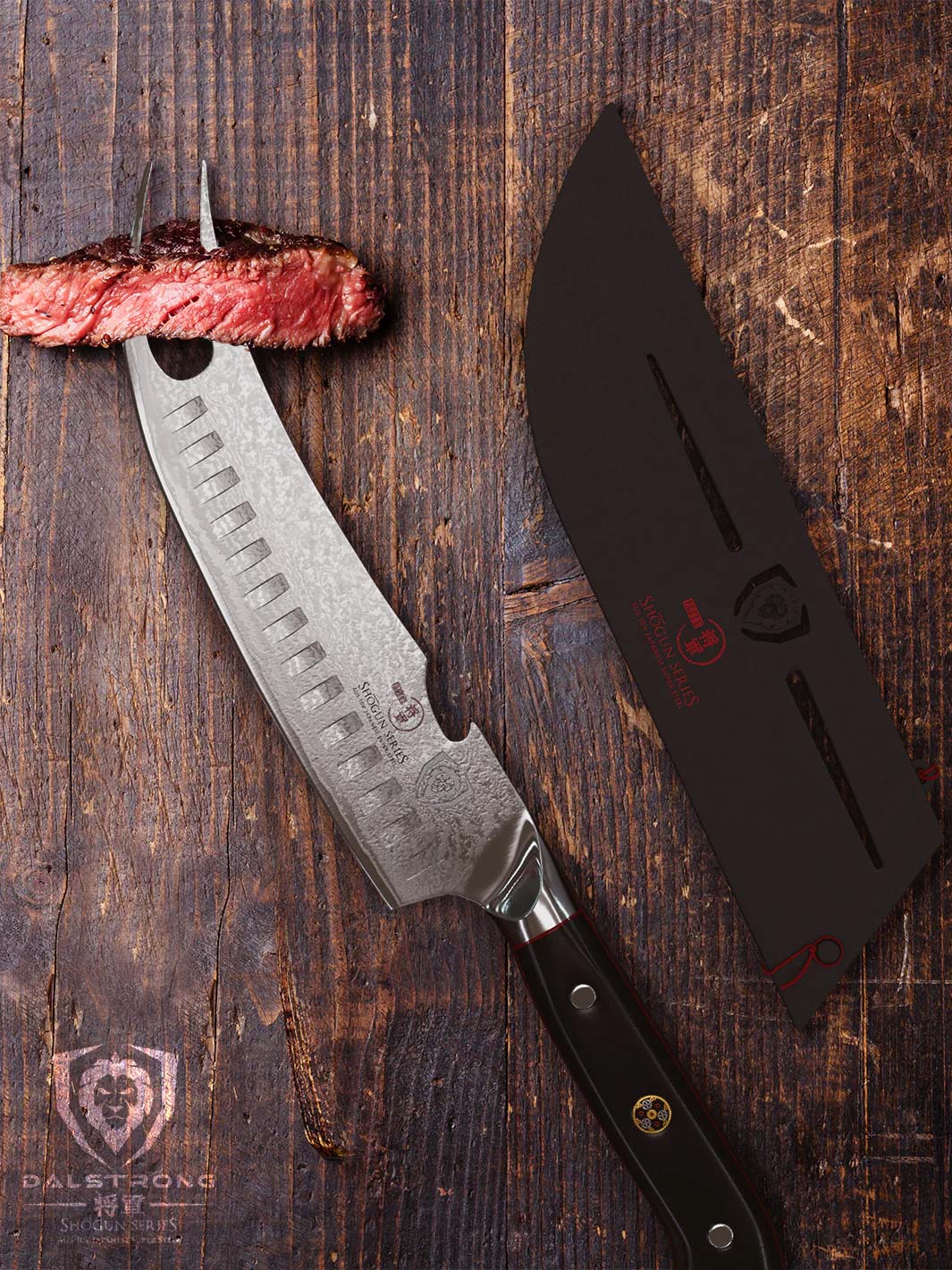

2. Lionswood- Teak Cutting Board | Dalstrong

This Tropical Teak wood board functions as your all-purpose chopping, slicing, and serving board. This meticulously hand-crafted end grain board is naturally resistant to water, bacteria, and staining.

Pros:

- Boasting 2 steel handles, this cutting board doubles as a carving board and serving board that is ideal for presenting your finest roasts, charcuterie, bread, cheese, and more.

- The wood used to make this board helps keep the blade of the knife sharp with every use.

- The tight-wood grain ensures a long-lasting hygienic cutting surface.

Cons:

- This is a medium-sized board. If you are looking to serve a larger party, you can go for a bigger chopping board.

- The board comes with a price tag that might not make this everyone’s first choice.

3. Lionswood Colossal- Teak Cutting Board | Dalstrong

This highly versatile board will make your meal prep a breeze. Substantial in weight and size, this board is filled with rich moisturizing oils that make it resistant to water, bacteria, and staining.

Pros:

- The unique checkered construction of the boards offers a slip-resistant surface that absorbs impact, ensuring knives stay sharper for longer.

- The underside of the board features a curved cut-out to house a side plate for easy scraping and transferring of ingredients.

- The massive board can also expand your cutting surface when placed over a sink, stove, or tabletop.

Cons:

- This board is bigger than the normal sized cutting boards and can be overwhelming for smaller kitchens.

- This board comes with a heavy price tag. You can also take a look at some of the more pocket-friendly cutting board options here.

4. Corner Cutting Board- Teak Wood | Dalstrong

This cleverly engineered cutting board is designed to reclaim space and fit snugly into the inner corner of your countertop. This board ensures that it stays in one place while you’re busy with a knife in your hand.

Pros:

- The end-grain fabrication prevents gouging in the board by allowing the wood fibers to spring back easily.

- The wood comes with natural antibacterial properties and ensures a long-lasting hygienic cutting surface.

- The board is designed to beautify with age.

Cons:

- This cutting board might be too bulky for compact kitchen.

- The board does not come with handles that can make it difficult to lift the board.